- Home

- Products

- Granite Machine Parts

- Granite Base

- Granite Lathe

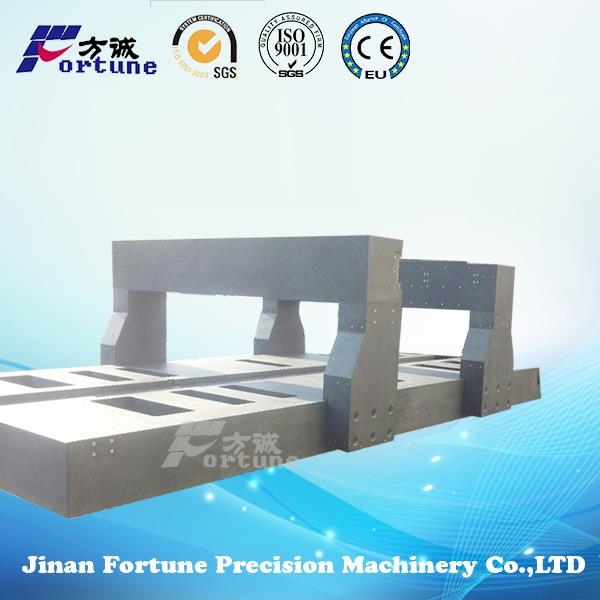

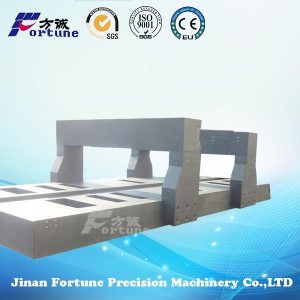

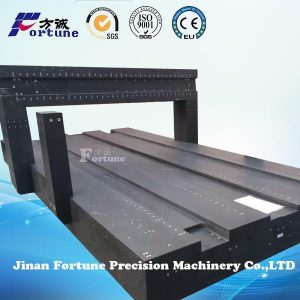

Granite Lathe

Granite Machine Tools: Why Choose Granite as the Base Material for Machine Tools?

In the field of machining where ultimate precision is pursued, traditional metal machine tools face inherent limitations such as thermal deformation and slow vibration damping. Precision granite lathes innovatively adopt natural granite as the core material for the bed, achieving revolutionary performance breakthroughs:

Exceptional Properties of Natural Granite:

Nearly Zero Thermal Expansion Coefficient: Far superior dimensional stability under temperature fluctuations compared to metallic materials.

Excellent Vibration Damping Capacity: Damping characteristics are 5-8 times higher than cast iron, significantly reducing machining vibrations.

Extreme Hardness and Wear Resistance: Mohs hardness of 6-7 ensures long-term accuracy retention.

Outstanding Stability: Free from internal stress, requiring no aging treatment, achieving a stable state immediately after installation.

Core Technological Advantages:

- Nanometer-Level Machining Precision

Our granite lathes feature a monolithic granite bed combined with a proprietary hydrostatic guideway system, achieving:

Straightness: ≤0.5μm/500mm

Repeat Positioning Accuracy: ≤0.3μm

Spindle Radial Runout: ≤0.1μm

- Temperature-Adaptive Machining Capability

The extremely low thermal expansion coefficient of granite, integrated with an intelligent temperature control system, ensures machining accuracy fluctuation remains within 1μm under ambient temperature variations of 15-30°C, completely solving the “thermal error” challenge.

- Ultra-Quiet and Efficient Machining

The exceptional vibration damping characteristics result in an exceptionally stable cutting process. Compared to traditional machine tools:

Vibration is reduced by over 70%

Surface roughness improves by 1-2 grades

Tool life is extended by 30-50%

Granite Machine Tools: Why Choose Granite as the Base Material for Machine Tools?

In the field of machining where ultimate precision is pursued, traditional metal machine tools face inherent limitations such as thermal deformation and slow vibration damping. Precision granite lathes innovatively adopt natural granite as the core material for the bed, achieving revolutionary performance breakthroughs:

Exceptional Properties of Natural Granite:

Nearly Zero Thermal Expansion Coefficient: Far superior dimensional stability under temperature fluctuations compared to metallic materials.

Excellent Vibration Damping Capacity: Damping characteristics are 5-8 times higher than cast iron, significantly reducing machining vibrations.

Extreme Hardness and Wear Resistance: Mohs hardness of 6-7 ensures long-term accuracy retention.

Outstanding Stability: Free from internal stress, requiring no aging treatment, achieving a stable state immediately after installation.

Core Technological Advantages:

- Nanometer-Level Machining Precision

Our granite lathes feature a monolithic granite bed combined with a proprietary hydrostatic guideway system, achieving:

Straightness: ≤0.5μm/500mm

Repeat Positioning Accuracy: ≤0.3μm

Spindle Radial Runout: ≤0.1μm

- Temperature-Adaptive Machining Capability

The extremely low thermal expansion coefficient of granite, integrated with an intelligent temperature control system, ensures machining accuracy fluctuation remains within 1μm under ambient temperature variations of 15-30°C, completely solving the “thermal error” challenge.

- Ultra-Quiet and Efficient Machining

The exceptional vibration damping characteristics result in an exceptionally stable cutting process. Compared to traditional machine tools:

Vibration is reduced by over 70%

Surface roughness improves by 1-2 grades

Tool life is extended by 30-50%

Latest News

Our Services

Our Services

Contact Us

Write Your Message